Process Solutions International (PSI) highlights its every application approach to industrial pumps, emphasizing the importance of selecting the right pump design—centrifugal, progressing cavity, or self-priming—based on specific fluid handling challenges. Through its PSI Max 2000 portfolio, the company supports diverse industries worldwide with purpose-built pump solutions designed to improve efficiency, reliability, and long-term performance.

Houston, TX, United States, 12th Feb 2026— Process Solutions International (PSI), a global provider of engineered fluid handling solutions, is reinforcing the importance of application-specific pump selection as industrial operations continue to diversify across sectors. Through its PSI Max 2000 industrial pump portfolio, the company emphasizes an “every application” approach, recognizing that no single pump design can effectively meet the demands of all industrial environments.

From high-volume fluid transfer to precision handling of viscous or solids-laden materials and challenging air-entrained conditions, PSI delivers multiple pump technologies engineered to perform reliably under distinct operational requirements. By offering centrifugal pumps, progressing cavity pumps, and self-priming pumps, PSI supports a wide range of industries, including oil and gas, wastewater treatment, mining, manufacturing, construction, and environmental services.

The Need for Purpose-Built Pump Designs in Modern Industry

Industrial fluid handling is rarely uniform. Facilities manage varying viscosities, solids content, flow rates, pressures, and environmental conditions often within the same operation. Selecting the wrong pump design can lead to inefficiencies, premature wear, excessive maintenance, and unplanned downtime.

PSI’s engineering philosophy centers on aligning pump technology with real-world application demands. Rather than promoting a one-size-fits-all solution, the company focuses on providing purpose-built pump designs that maximize performance, efficiency, and operational longevity. This application-driven approach allows industrial operators to maintain process integrity while adapting to evolving production requirements.

Centrifugal Pumps for High-Flow and General Transfer Applications

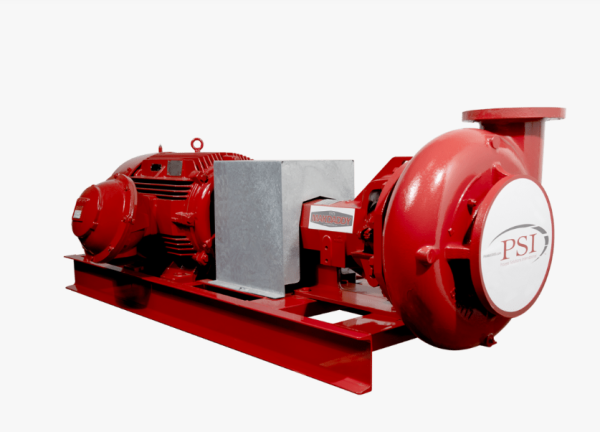

Centrifugal pumps remain one of the most widely used pump types across industrial environments due to their versatility and efficiency. PSI’s MakDaddy centrifugal pumps are designed to support applications requiring consistent, high-volume fluid movement with minimal complexity.

Operating through a rotating impeller that imparts kinetic energy to the fluid, centrifugal pumps are well-suited for clean or lightly contaminated liquids. These pumps are commonly deployed in water transfer, circulation systems, cooling processes, and general plant services where steady flow and dependable performance are essential.

PSI’s MakDaddy centrifugal pump line is engineered for durability in demanding environments, making it a practical choice for manufacturing facilities, water treatment plants, and oilfield support operations. Their straightforward design also contributes to reduced maintenance requirements and long-term operational efficiency.

Progressing Cavity Pumps for Controlled Flow and Challenging Fluids

Not all industrial fluids behave the same way. Applications involving thick, abrasive, shear-sensitive, or solids-laden materials require a pump design capable of maintaining precise, consistent flow under variable pressure conditions. For these challenges, PSI offers MAX2000 progressing cavity pumps.

Progressing cavity pumps are positive-displacement pumps that move fluid through a continuous sequence of sealed cavities formed between a helical rotor and a stator. This design enables smooth, pulse-free flow and accurate metering, regardless of changes in discharge pressure.

PSI’s progressing cavity pumps are widely used in wastewater treatment, oil and gas drilling operations, mining, chemical processing, and food production. They excel at transferring sludge, drilling mud, slurries, pastes, and other difficult materials that may cause inefficiencies or damage in centrifugal pump systems.

The MAX2000 design incorporates robust construction and specialized sealing technology to enhance reliability and minimize contamination risks. This makes progressing cavity pumps a critical component in processes where flow consistency, material integrity, and equipment longevity are priorities.

Self-Priming Pumps for Air-Entrained and Variable Suction Conditions

Certain industrial applications introduce air into the pumping system or operate under fluctuating suction conditions. Sump drainage, tank emptying, dewatering operations, and processes with intermittent fluid levels require pumps capable of evacuating air and restoring suction without manual intervention.

PSI’s MakDaddy self-priming pumps are engineered to handle these scenarios effectively. By incorporating internal air-handling mechanisms, self-priming pumps can separate air from liquid and re-prime automatically, even after shutdowns or loss of suction.

This capability simplifies installation, reduces reliance on auxiliary priming systems, and minimizes downtime.PSI’s self-priming pump solutions provide dependable performance in mixed air and fluid environments, helping operators maintain continuous operation under challenging conditions.

Supporting Industrial Operations Across Global Markets

PSI’s industrial pump solutions are deployed worldwide across diverse industries and operating environments. From municipal infrastructure and industrial manufacturing to energy production and environmental remediation, the company’s pumps support critical processes that demand reliability and consistency.

The availability of multiple pump designs within the PSI Max 2000 portfolio allows customers to standardize sourcing while still addressing varied application requirements. This flexibility supports scalability and operational continuity for organizations managing complex or multi-site operations.

About Process Solutions International

Process Solutions International (PSI) is an international provider of engineered industrial process equipment and fluid handling solutions. With decades of industry experience, PSI delivers high-performance systems designed to meet the demands of modern industrial environments. PSI serves customers globally with a focus on quality engineering, application expertise, and long-term operational value.

For more information, visit: https://psimax2000.com

Facebook: https://www.facebook.com/processsolutionsinternational

LinkedIn: https://www.linkedin.com/company/process-solutions-international/

Media Contact

Organization: Process Solutions International

Contact Person: Kye Keliehor

Website: https://psimax2000.com/

Email: Send Email

Contact Number: +12818934774

Address:7519 Prairie Oak Dr

City: Houston

State: TX

Country:United States

Release id:41283

The post PSI Highlights Use of Multiple Pump Designs to Support Diverse Industrial Environments appeared first on King Newswire. This content is provided by a third-party source.. King Newswire makes no warranties or representations in connection with it. King Newswire is a press release distribution agency and does not endorse or verify the claims made in this release. If you have any complaints or copyright concerns related to this article, please contact the company listed in the ‘Media Contact’ section

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Funds Special journalist was involved in the writing and production of this article.